-40%

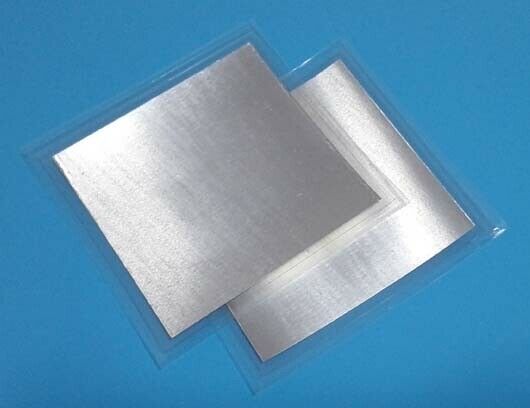

1600W/mK pyrolytic graphite sheet, 0.025×300×300mm, high thermal conductivity

$ 15.31

- Description

- Size Guide

Description

Over 100 sold!Fast USPS shipping from USA. (Buyer pays customs/import duties, if any for international sales)

Thickness: 25μm

Size: 300×300mm

Planar thermal conductivity: 1600W/mK

Vertical thermal conductivity: 15-20W/mK

Operating temperature: up to 120°C

Matte side: electrical insulation layer, safe to contact circuitry/components.

Shiny side: plastic backing, peel away to reveal sticky backside to adhere to your components. The adhesive side is also electrically insulating.

Use cases: cooling of laptops, tablets, smartphones, and other electronics

As featured in the popular MateBook X Pro laptop cooling mods on BradsHacks .com, these pyrolytic graphite sheets have incredible thermal conductivity:

1600W/mK

— 4 times that of copper. Therefore, they are excellent at spreading heat and smoothing out hot spots.

My readers and myself have previously resorted to the Panasonic PGS graphite sheets from Digikey, which are to for a 180×115mm sheet. Now, I've managed to source these sheets by manufacturer AOQ, directly from China. They have the

exact same thermal conductivity

compared to the Panasonic counterpart of the same thickness, but these sheets are

4.4 times the size

. I'm selling these at

a quarter of

the price

of the Panasonic per unit area. Also because of the large size, you get a contiguous area instead of separate pieces, for even better heat spread.

Be sure to check out the heat pipes that I'm also selling at a discount! If you're using graphite sheets, you could probably also use some heat pipes. Order them together and save on shipping!

Third-party verification document showing 1820.559W/mK in the raw material which lowers to 1600W/mK once packaged into the sheet product.